3D Printing FAQ

Frequently Asked Questions

Which file types can I upload for an instant quote?

You can upload OBJ, STL or STEP files, these are the standard files used in the 3D printing industry.

Note: As STL files don’t contain information on what measurement unit was used to create the model, it is important that you know which measurement unit your 3D program uses in mm, cm or inches before you export it.

Once you have completed the export, you can upload a 3D design for printing and specify the measurement units in mm, cm or inches within the instant quote tool.

Do you offer trade accounts and payment terms?

Yes, subject to minimum spend requirements and credit checks. Please contact us to discuss your requirement.

My project is secret, will you sign a Non-Disclosure Agreement?

YES!

Although we take privacy seriously and will not share your prints on social media or on our websites without your express permission, we also realise you may want something on paper. We’re happy to provide a pre-signed NDA or can review and sign yours. Please contact us if you need us to review your NDA.

What material should I use for my project?

There’s a huge range of 3d printing materials available, from cost effective prototyping plastics such as PLA, to materials more suited to permanent outdoor use such as ASA. You can learn about our 3D printing materials and technologies on our materials page.

If you are unsure of what material to use, contact us with your project details and we can advise a suitable material.

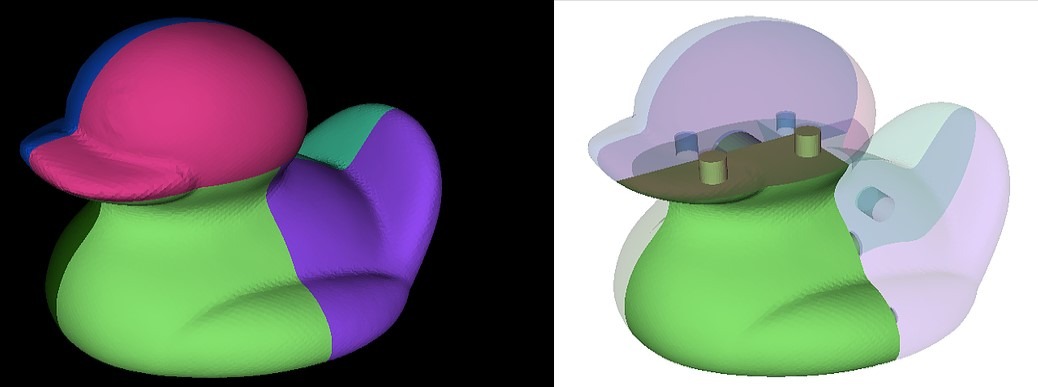

Can you print in colour?

Yes we can….to a point. Whilst full colour printing requires special equipment a multi colour print is possible with our machines. If you have a specific requirement please contact us to discuss.

Full colour printers are generally used for visual representation models rather than functional parts. For functional polymer parts, we believe it is better to 3D print them in a strong plastic material and add colour afterwards — either through a dyeing process for block colours or painting for an application-specific finish.

Can you print large 3d prints for visual merchandising or marketing applications?

Absolutely!

We’ve invested heavily in expanding our large format 3d printing capabilities for exactly this purpose. Whilst we can print up to 1M cubed, 1.2M tall or 1.2M long, we can also split your 3d model to sections, print and re-assemble opening up HUGE possibilities for eye catching supersized 3d prints which really stand out.

Can I have a smooth glossy finish?

An FDM/FFF printed part will show layer lines and surface marks where the lines of plastic have been drawn by the print head, however for the majority of applications, this isn’t a major concern. A smooth finish can be achieved with filler primer spray paint and wet and dry sanding before applying a finishing coat of your desired colour. Model makers and designers often use this approach for the majority of their 3D prints.

Smoother prints can be achieved with SLA (resin) prints, with only minor sanding needed to remove support material marks where the supports touch the part during printing.

How do I know if my 3D design is suitable for printing?

When you upload your 3D design for printing, we check each file for holes (non-manifold geometry) before production. This initial check is to ensure that your model is a so-called solid mesh – a model where all the edges of the polygons that build up the model are connected to one-another (manifold geometry). We also look out for issues with the design and will get back to you if any amendments are necessary.

Nevertheless, we highly recommend ensuring that your file meets the basic design requirements for 3D printing beforehand. If you’re unsure, take a look at our quick guide for fixing stl files for free!.

Is 3D Printing Fast?

3D printing is fast, if you compare it to other methods of manufacturing, however, the quickest we can generally turnaround a small(ish) print is about 24 hours. The process is not like using an inkjet printer as all detailes are drawn in layers. Models with more details, finer print resolution, increased infill and of course larger physical size, will all play a part in defining the amount of time needed to print.

Some parts can be printed in a number of hours, but these are usually only smaller and draft resolution items at 300 microns layer height, this makes it unlikely for you to be able to call up and collect a print a few hours later, but it isn’t impossible!

We generally require 3-5 days for more prints (which is still super fast for manufacturing!)

What is the smallest hole you can print?

For short holes that are open both ends, we recommend around 2mm.

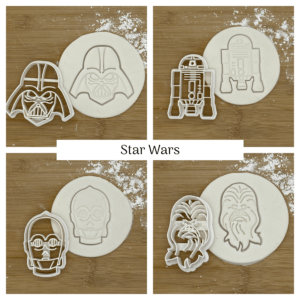

Are your materials certified food safe?

Whilst materials such as PETG are advertised as food safe, and it is certainly true that the material doesn’t harbour bacteria in the same way other 3d printed materials can, the 3d printing process has itself isn’t certified as a food safe process. Officially therefore, we can’t recommend 3d printed parts for long term food processing applications.

Having said that….. there’s lots of examples of people using PETG for short term applications such as cookie cutters where thorough washing between uses is recommended. We’re not aware of anyone having an issue following the use of one!

Are 3D printed products strong?

Prints can be extremely strong with the right use of materials and print settings.

In general, materials such as PETG or ABS provide the best results from our range, although engineering resins and carbon infused materials are also great options depending on your application and budget.

However, 3D printing is a layer by layer process, which means that you effectively have a grain – and where there is a grain, there is weakness, especially on thin features. The easiest way to visualize this is to imagine that your part is made out of Lego. If you make your wall very thin, you cannot easily break the wall by adding pressure from the top or down the length of it, but if you push from the side of it, the wall will buckle easily and break. This is the same with 3D printing – to get around it you can either orient the part at a different angle (being humans, we will always do this for you if we notice a weak point on your model, though it is not guaranteed that we will notice everything), or you can thicken the wall up considerably – just like if it were Lego.

What did we miss?

If you have a question we haven’t covered here, please contact us via email or give us a call on 01785 594389.